Negritos LiDAR

Description

Equipment Type: LiDAR MeteoLaser Ammonit

Total height: 160 meters

Other information:

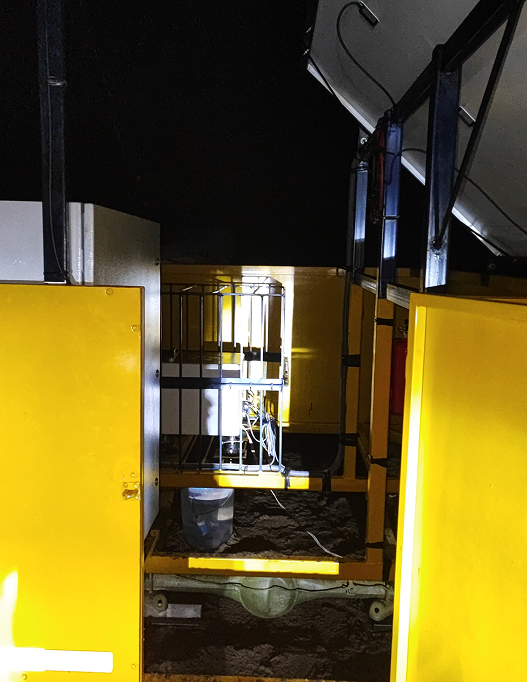

- Autonomous photovoltaic power system composed of a 460 W solar panel, four 12V-100Ah deep cycle batteries (total 200 Ah in 24 Vdc), and a charge controller module that supplies 24 Vdc to the Lidar.

- Automatic cleaning system for LiDAR optical components with a submersible pump, a glass cleaning arm and a 20-litre water container.

- Surveillance system with cameras and specialized service with personnel in the field.

Type of Service

Installation of LiDAR system for wind measurement activities

Date

May 2025

General Data

Negritos, Talara, Peru • 2025

Instrumentation

- Temperature, humidity and atmospheric pressure sensor.

- Electrical Cabinet

with IP65 protection.

- External modem

for communication and internet access.

- SMA antenna.

- Grounding, ethernet, and power cables.

- Security Camera

for surveillance.

- Data logger

The data is stored in the device’s memory and uploaded to the Ammonit AmmonitOR cloud.